Fiber Laser

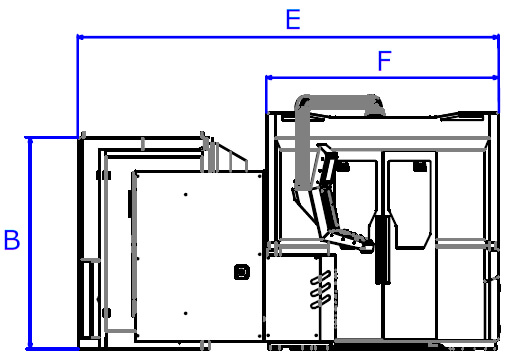

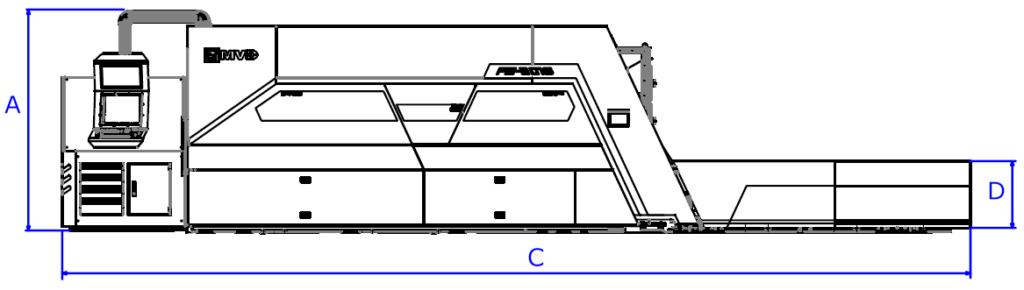

Ready to Start Machine, laser source, head & control – all connected during transport Compact, Fits in a regular truck, less installation time, less foot print Operator friendly, easy open side covers and for easy maintenance access. Making sure of starting the machine same as factory settings and adjustments. Designed with high precision criteria, rigid body. Power transmission by Rack & Pinion system.

Cutting Head

World’s most known and trusted Precitec ProCutter Laser Cutting Head

Led Status Indicators

- Motor system state

- Head temperature

- Pressure

- Glass heat/pollution status

Protective Glass

Protecting the optics against dirt and fume, monitoring of attendance and contamination, tool-free, easy change cartridge

Auto Height Adjusting Sensor

Keeping the cutting height same all over the sheet metal,

assuring high-quality cuts by the capacitive sensor in the head.

Auto Motorised Focus System

Motorized focus position adjustment for automatic machine

setup and piercing work.

Smart status display

Real-time status monitoring over the CNC panel or

mobile app.

CNC Control Unit

ESA and LYNCA CNC Controllers 21” wide touch screen, with

easy use panel design all controls are at your fingertips.

Camera Monitoring System

By remote access or next to the control panel,

you are able to watch the work process real-time.

CNC Control Unit

- Windows operating system

- Multi-touch graphic screen

- Multifunctional keyboard, button/joystick/speed potentiometer

- EtherCAT communications for data transfer or machine control

- Enhanced Database for cutting parameters, for different type

materials and thicknesses - Fly Cut functions for same direction high-speed cutting

- “No Piercing” technology for thin materials, efficiency time and

cost improvements - Better results at thick cuts, by prioritizing all piercings process before

regular cutting - Remote connection to PC

- Multi-language support

- Enhanced sheet metal recognition software

- Referencing and sheet alignment functions

- Setting different user-login levels for operators/maintenance/admin

- Multi-functional workpiece job order search/recall function

Power Source

Perfect Cutting Perfect Beam Quality

Multi Mode Fiber Laser Resonators

- IPG, nLight and Raycus various resonator options

- Optimum focus diameter

- Maintenance free technology,

- Continuous perfect beam quality

with a laser beam is transmitted by the fiber core through the

fiber cable. - High efficiency, low consumptions of electricity fiber laser

technology, 5-6 times the lower runnig cost - Possibility to cut Steel, Stainless Steel, Aluminum,

Copper Brass, Titanium and various materials

Chiller Unit

PG or OMI options

Digital micro processing controlled industrial purpose chiller unit

Cad/Cam Software

IPG or OMI options

Digital micro processing controlled industrial purpose chiller unit

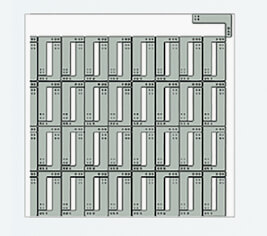

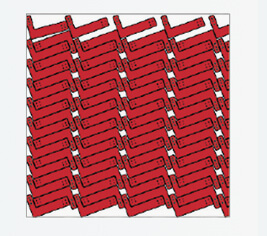

Automatic Part Nesting

- Libellula and Lantek options

- Offers perfect nesting efficiency for automatic or manual part nesting

- Copy, move, reverse, turn alignment manual, semi-automatic,

functions geometrical working - Advanced nesting algorithm optimizes the use of

a material, minimizing scrap. - Can work with standard sheets stocked in the warehouse and/or with

scraps obtained from previous processes.

High Accuracy, Speed and Stability

- Automatic cutting path determination

- Time/Cost analyses

- Simulation before actual cutting

- Smart Part importer / Exporter from CAD system, DXF, DWG,

IGES, Step etc file formats - Part Drawing module, call parts, automatic or manual nesting,

machining, CNC codes generates, Sheet metal stock searching etc - Various input/output methods, film burning, specialized piercing,

fast laser, micro-joints, head direction management, edge binding - Complicated functions and programmable cad cam system for

Common cut, micro joint, lead in lead out parameters

Automatic Camera Nesting and Referencing

The advanced camera system can recognize and measure the location, size of a randomly placed sheet on the table.

Allows you to place and do nesting for parts Helps you start just in a few seconds

Technicial Specifications