Characteristics

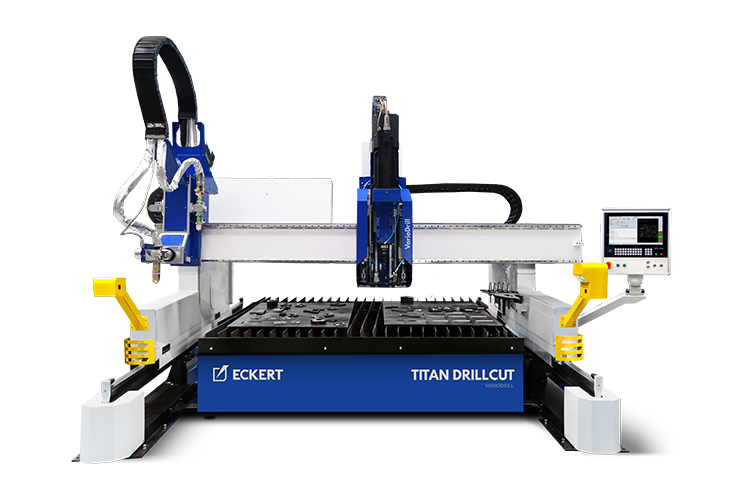

The DrillCut machine is an advanced sheet metal processing center that combines the latest capabilities in thermal cutting and machining, ensuring precise hole drilling without material hardening.

Individually configurable with plasma and oxy-fuel cutting tools, as well as a powerful VarioDrill drilling unit with drilling, tapping, and countersinking functions, it enables comprehensive autonomous processing of components.

The VarioDrill drilling unit is used when higher drilling accuracy is required, the drilling diameter is smaller than the material thickness, or the number of thermal piercings needs to be reduced.

Main features:

- Processing of materials up to 200 mm thickness

- Precise drilling without heat impact in accordance with DIN EN 1090-2

- Drilling Ø6-40 mm, tapping M4-M20, fillet countersinking, and flat countersinking

- Automatic tool change with a 6-position tool magazine

- CNC automation combining drilling and cutting in a single program

- The machine is designed for 24/7 continuous operation in four shifts, making it the ideal choice for heavy industry and customers with high operational demands

- Designed for high-performance plasma cutting sources up to 800 A

- Efficient and user-friendly PC-based CNC control system

- Meets comprehensive safety and environmental standards

- High standards in wiring and documentation

Technology

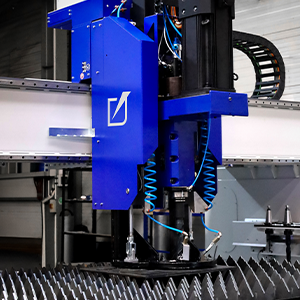

VarioDrill suport

Support, equipped with features such as automatic calibration and systematic monitoring of tool wear during drilling, ensures maximum precision and repeatability of the machining process. Integrated pneumatic clamping eliminates material movement and vibration, and incremental encoders accurately determine the distance between the sheet and the tool, enhancing drilling and tapping quality. In addition, a chip blow-off system and operator safety guard guarantee clean and safe operation.

Automatic tool changer

The six-tool magazine with an advanced exchange mechanism adapts to the machining process in real time. A cavity occupancy detection sensor and automatic switching between drilling, tapping and countersinking eliminate the need for operator intervention, ensuring maximum machining efficiency and precision.

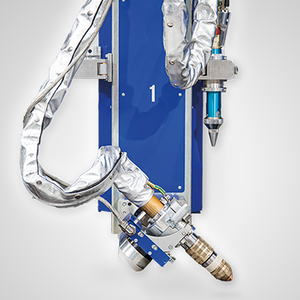

Dual Flex 3D Head

Dual Flex 3D is an all-purpose tool with exchangeable torches which allows for 3D plasma and oxygen cutting. Torch’s exchange takes only a few seconds. The application of one support for two cutting head extends the working area and extends the range of possibilities for cutting and bevelling sheet metal, pipes and profiles. An unlimited rotation and head angle deflection +/- 52° significantly increase the cutting process, especially for the production many elements on one sheet.

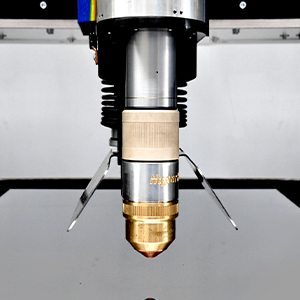

HD 3000 Support

Support HD3000 enables full utilisation of the state of the art plasma torches. Application of the ball screw gear and high torque servomotor is the unique drive and support leading in Z axes resolution, which allows for more dynamic and increased accuracy in the torch control. This guarantees the perfect distance between the cutting head and the material for maximum cutting quality. Support HD3000 is equipped with sensors: anti-collision, electrical/mechanical touch and height sensor. This allows using technologies such as: Contour Cut®, Contour Cut Speed®, Diameter Pro® and True Hole®.

Oxygen torch

Oxygen torch is the cutting solution destined to cut structural low-carbon and low-alloy steel. It is capable of processing wide range of material thickness. The torch was fitted out the height sensor, automatic ignition and possibility of manual angle setting.

Eckert i-Vision controller

Modern industrial device equipped with a robust touchscreen made of Corning® Gorilla® Glass, designed for use in harsh environments. Thanks to its powerful components and proprietary software with extensive features and an intuitive user interface, it allows full utilization of the machine’s capabilities while ensuring reliable operation. The controller is mounted on an adjustable arm with a height range of +/- 300 mm, improving ergonomics for the operator and enabling comfortable control and monitoring of the cutting process.

Construction

The machine has been designed to operate in extreme heavy duty conditions. A reinforced structure and a portal designed to absorb heavy loads, combined with appropriate safety features, guarantee stability during drilling. As a result, the machine can perfectly handle even very thick and hard materials.

Cutting machine specifications

| Type of cutter | DrillCut |

| Drives | Servo AC |

| Available cutting width | 2.000-7.000 mm |

| Available cutting length | Any length from 1.500 mm |

| Positioning speed | 25.000 mm/min |

| Cutting thickness | up to 200 mm |

| Cutting quality | EN ISO 9013 |

| Standard Compliance for Steel Structures | EN 1090-2 |

| Positioning accuracy | EN 28206 |

| Repeat accuracy | EN 28206 |

| Performance-Level according EN 13849-1 | PL d |

| Safety – Emergency stop | EN 13850 |

| Wiring Diagram | EN 81346 |

| Working table height | 740-760 mm |

| Ambient temperature | + 5 °C to 45 °C |

| Relative humidity | max. 90% – without condensation |

Drill specifications

| Type of drill | VarioDrill |

| Drill range | Ø 6.0 mm – Ø 32.0 mm (Ø 40.0 mm) |

| Tapping range | M8 – M20 |

| Pneumatic clamping | 2 x 1570 N |

| Tool storage | 6 items |

| Tool grip | SK 40 / ISO 40 (DIN 69871) |

| Drill tool measurement | Automatic calibration |

| Engine power | 9.3 kW |

Standard plasma power supplies

| Hypertherm | Max. piercing | Max. from the edge |

| Powermax 45 SYNC | 12 mm | 29 mm |

| Powermax 65 SYNC | 16 mm | 32 mm |

| Powermax 85 SYNC | 20 mm | 38 mm |

| Powermax 105 SYNC | 22 mm | 50 mm |

| Powermax 125 | 25 mm | 57 mm |

| MaxPRO 200 | 32 mm | 75 mm |

| XPR 170 | 40 mm | 60 mm |

| XPR 300 | 50 mm | 80 mm |

| XPR 460 | 64 mm | 102 mm |

| HPR 400 XD | 50 mm | 80 mm |

| HPR 800 XD | 50 mm | 80 mm |

| Kjellberg | Max. piercing | Max. from the edge |

| HiFocus 161i Neo | 30mm | 50 mm |

| HiFocus 280i Neo | 40 mm | 70 mm |

| HiFocus 360i Neo | 50 mm | 80 mm |

| HiFocus 440i Neo | 50 mm | 120 mm |

| HiFocus 600i Neo | 80 mm | 160 mm |

| SmartFocus 130 | 25 mm | 40 mm |

| SmartFocus 170 | 30 mm | 50 mm |

| SmartFocus 200 | 30 mm | 60 mm |

| SmartFocus 300 | 40 mm | 80 mm |

| SmartFocus 400 | 50 mm | 100 mm |

| Q1500 | 30 mm | 60 mm |

| Q3000 | 50 mm | 80 mm |

| Q4500 | 50 mm | 120 mm |

Given data depends on the material involved and its structure. The ability to pierce depends on the material, thickness and also height sensor, and drive.