Characteristics

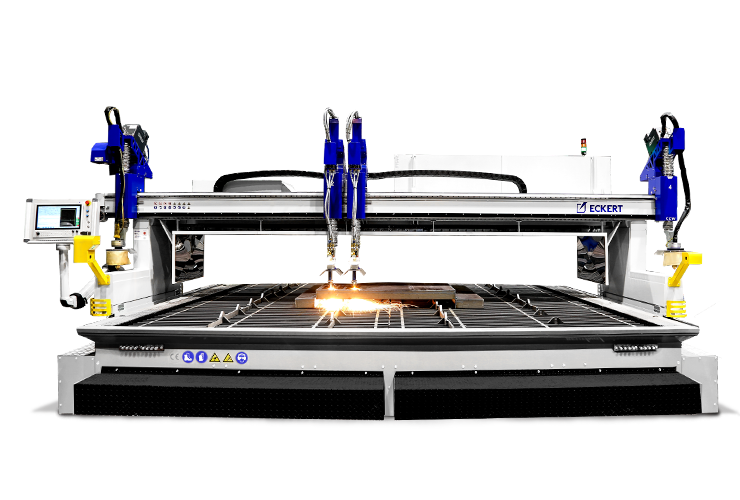

Zircon Extreme is an advanced machine designed for heavy industry and intended for continuous operation in a four-shift system (24/7). It was developed for customers who expect the highest precision and repeatability in cutting, even under particularly high load and demanding working conditions.

Key Features

- Suitable for Intensive Use:

The machine is designed for continuous 24/7 operation in four shifts, making it an ideal choice for heavy industry and clients with high operational demands. - Maximum Precision:

Ensures the highest cutting accuracy through numerous technical innovations, even under heavy load, which is essential in many industrial applications. - Consistent Cutting Quality:

Maintains high cutting quality even when processing materials with high initial temperatures. - High Safety Standards:

Protects operators and minimizes the risk of workplace accidents. - Top Standards in Wiring and Documentation:

This enables independent maintenance by customer personnel worldwide, increasing operational independence and flexibility. - Cuts Materials Up to 300 mm Thick:

The ideal choice for demanding applications, including multi-torch operations. - High Efficiency of Plasma Cutting Sources up to 800 A:

Ensures fast and effective cutting of very thick materials.

Technology

Plasma support

The plasma support offers state-of-the-art solutions in terms of precision, safety, and reliability. The system is designed with maximum safety in mind – installed shields protect against splashes and blinding reflections, while special protective bellows made of flame-resistant material safeguard the mechanics from damage and high temperatures.

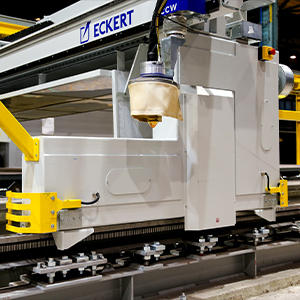

Camera system and temperature sensors

The built-in positioning camera assists in the precise positioning of the torches, which helps in quickly and comfortably determining reference points. A temperature sensor detects the sheet metal temperature to achieve optimal manufacturing accuracy, taking thermal expansion into account.

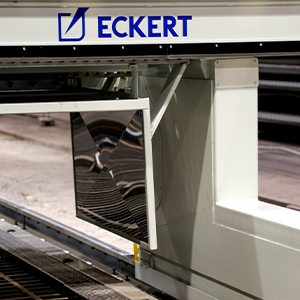

Temperature management system

The advanced active cooling system, using temperature sensors and fans, ensures a constant temperature inside and below the machine portal, even under extreme working conditions. This minimizes the risk of overheating electrical wiring and other electronic components, while ensuring consistent repeat accuracy.

Heat shields

The additional heat shield effectively protects the machine from direct thermal radiation. The layers of ceramic fibers used for this purpose are located under the machine portal and carriages.

Construction

The portal, specially designed for the most challenging working conditions, made from welded steel profiles, offers exceptionally high rigidity while maintaining low weight. The heavy-duty package, along with robust drives and racks, further increases the machine’s reliability and durability. Thanks to this design, the machine maintains its high performance and precision even under extreme loads.

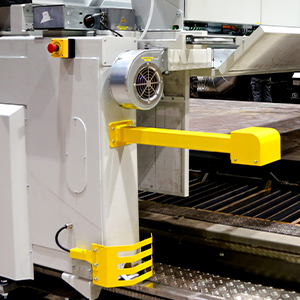

Eckert i-Vision controller

Modern industrial device equipped with a robust touchscreen made of Corning® Gorilla® Glass, designed for use in harsh environments. Thanks to its powerful components and proprietary software with extensive features and an intuitive user interface, it allows full utilization of the machine’s capabilities while ensuring reliable operation. The controller is mounted on an adjustable arm with a height range of +/- 300 mm, improving ergonomics for the operator and enabling comfortable control and monitoring of the cutting process. Furthermore, the Tropic/Frost system maintains the optimal temperature of the controller, increasing its durability and operational stability.There is also the possibility of integrating the controller with an additional computer that supports production planning systems like ERP and MES.

Technical data

| Model | Zircon |

| Drives | Serwo AC |

| Cutting width | 2 000-7 000 mm |

| Basic working length | from1500 mm |

| Positioning speed | 25000 mm/min |

| Cutting thickness | up to 300 mm |

| Cutting quality | DIN-EN ISO 9013 |

| Positioning accuracy | DIN-EN 28206 |

Standard plasma power supplies

| Hypertherm | Max. piercing | Max. from the edge |

| Powermax 45 SYNC | 12 mm | 29 mm |

| Powermax 65 SYNC | 16 mm | 32 mm |

| Powermax 85 SYNC | 20 mm | 38 mm |

| Powermax 105 SYNC | 22 mm | 50 mm |

| Powermax 125 | 25 mm | 57 mm |

| MaxPRO 200 | 32 mm | 75 mm |

| XPR 170 | 40 mm | 60 mm |

| XPR 300 | 50 mm | 80 mm |

| XPR 460 | 64 mm | 102 mm |

| HPR 400 XD | 50 mm | 80 mm |

| HPR 800 XD | 50 mm | 80 mm |

| Kjellberg | Max. piercing | Max. from the edge |

| CutFire 100i | 20 mm | 40 mm |

| K200 | 30 mm | 60 mm |

| HiFocus 161i Neo | 30 mm | 50 mm |

| HiFocus 280i Neo | 40 mm | 70 mm |

| HiFocus 360i Neo | 50 mm | 80 mm |

| HiFocus 440i Neo | 50 mm | 120 mm |

| HiFocus 600i Neo | 80 mm | 160 mm |

| SmartFocus 130 | 25 mm | 40 mm |

| SmartFocus 170 | 30 mm | 50 mm |

| SmartFocus 200 | 30 mm | 60 mm |

| SmartFocus 300 | 40 mm | 80 mm |

| SmartFocus 400 | 50 mm | 100 mm |

| Q1500 | 30 mm | 60 mm |

| Q3000 | 50 mm | 80 mm |

| Q4500 | 50 mm | 120 mm |

| Thermal Dynamics | Max. piercing | Max. from the edge |

| UltraCut 130 XT | 25 mm | 40 mm |

| UltraCut 200 XT | 40 mm | 65 mm |

| UltraCut 300 XT | 45 mm | 75 mm |

| UltraCut 400 XT | 50 mm | 90 mm |

Given data depends on the material involved and its structure. The ability to pierce depends on the material, thickness and also height sensor, and drive.